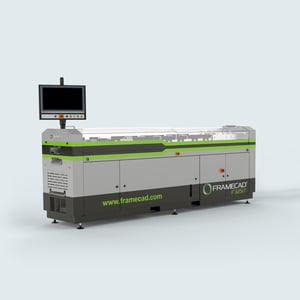

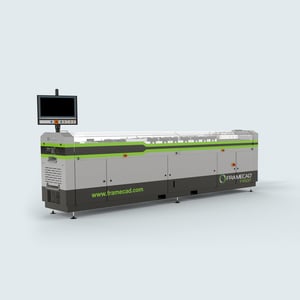

Roll Forming Steel Framing Machines

Your projects demand accuracy, reliability and high productivity. You can rely on our solutions to simplify the building process, ensuring high standards with minimal manual intervention. Advance your business with our steel framing solutions, and framework, to deliver consistent results for your clients through a streamlined building process.

Precision

Steel frames are crafted with precision to guarantee accurate, consistent results in every project, delivering exceptional performance and reliability.

Efficiency and Speed

Complete projects on time and within budget with our high-speed, automated construction equipment. Designed to minimize manual labor and maximize output, our steel framing machines boost your project's efficiency.

Versatility and Flexibility

No matter what your project requires, our roll forming machines and versatile equipment lets you take on a wide range of projects. From residential to commercial construction, interior to exterior, our light gauge steel framing machines meet all your construction needs with confidence.

Manufacturing Process Matched to What You Want to Build

Let's talk about the right machine for you.

Production Management

With our roll-forming equipment, you benefit from the world's first production management platform for steel framing. You will have complete visibility and control of your operations with quality control, capacity management, and real-time project data so you can build trust and confidence between contractors and customers.

Helping Customers in Over 100 Countries for Over 35 Years

USG LATAM is reshaping the construction industry across Latin America.

Orlando Steel Framing sees time-saving as one of the biggest advantages of steel framing.

ICS engineers, designs and manufactures prefabricated buildings across the US.

Intellisteel offers a comprehensive range of services that extend from turnkey modular solutions to off-site and on-site applications.

Intellistructure specializes in providing innovative steel framing and structural components to the East Coast of the US.

Accurate Steel Fab manufactures pre-panelized steel components for residential and commercial sectors across Texas.

Do-it-yourselfers are buying steel framing house kits from Frame Up Now and constructing their own house framing onsite.

Side-by-Side and End-to-End

Access training modules and tutorials to enhance your team's knowledge and skills on the FRAMECAD Solution.

Customer Success team members are positioned around the world to support your business.

Your one-stop portal for support, Nexa, the Knowledge Center, shop, and training videos.

Frequently Asked Questions

The 3-1/2” and 5-1/2” studs are typically used for the residential construction market, while the 3-5/8” and 6” are mainly used for the commercial market. There is no scientific or technical reason for that at all. It is just industry practice. One needs to be careful as most doors and windows (and other hardware) are manufactured for 3-1/2” and 5-1/2” studs (for the residential market). If one tries to use different size studs, major issues may arise. The same goes for the commercial market.

The span rating for a webbed joist or truss depends on several factors. The span depends on the applied loads, joist/truss spacing, thickness of steel, depth of the joist/truss and the strength of the steel. One can achieve whatever span the design calls for by varying one or more of the variables (parameters) mentioned.

Yes. FRAMECAD offers several dedicated profile systems to construct mid-rise buildings. The main profiles for such buildings are the 6”, 12 or 14-gauge (97 or 68 mil) and 3-5/8”, 20-gauge (33 mil) profiles. With these two profiles one can easily design and construct multi-level buildings. It is essential to plan the project first and to get the architect and all trades involved early in the design process so that there are no modifications, re-work, or unnecessary reinforcements required in the field. There may be a few locations in the builidng where hot rolled steel may be required. Cold-formed steel is typically used where it makes a design and economic sense.

Each system has its pros and cons. Dedicated profile systems are extremely efficient and productive. They require less steel coil inventory, less training, less change out times, less maintenance, and less skilled operators. Multi-profile systems on the other hand, are more complex in nature, though they produce more profiles. They do require more training, require experienced operators, more steel coil inventory and more change-out time (less productive). With dedicated profile systems you can double or triple the output (with 2 or 3 systems), something you cannot do with a single multi-profile system.

Both joists can be used for the residential and commercial markets. Webbed joists require more labor but can be fabricated using any FRAMECAD system. Deep C-joists on the other hand, require less labor but can only be produced by one heavy platform system. Trades can be easily installed within a webbed joist system. For the C-joist system, a large service hole is required to install the trades (thus resulting in a heavy platform system). The span for webbed joist systems can be increased by increasing the depth of the joist (among other parameters). The depth of the C-joist is for most cases limited to one or two sizes.

The building codes and standards require manufacturers or suppliers of building products to develop a quality program to ensure that their products meet the minimum requirements of the building code. The ICC certification is a process where a third-party certification and auditing agency is engaged to ensure that the steel profiles printed by the FRAMECAD systems comply with the code requirements. This certification and auditing process includes a traceability check of the steel profiles from cradle to grave to ensure that quality steel and robust processes are used for every profile installed in the construction of a structure.

FRAMECAD has a network of certified engineering consultants that can help you with the design of your building. These consultants have been trained in the efficient use of the FRAMECAD system and its software. Most of these consultants are experienced in manufacturing design, which is essential for the efficient and effective use of cold-formed steel framing. The Cold Formed Steel Engineers Institute (CFSEI) also has a list of experienced practicing engineers in the cold-formed steel industry (that may or may not be experienced with the FRAMECAD system).

Buying steel coils is an art. Some education on steel purchasing is required. Steel coils are typically purchased from service centers. Some large fabricators may be able to buy directly from steel mills or large roll formers. Some fabricators purchase steel from offshore companies and mills. The things to consider when buying steel are to ensure steel coil compliance with international standards (such as ASTM standards), ensure the minimum thickness, strength and galvanized coating conform to the design specifications, and to ensure the exact coil width is supplied. The ICC certification covers all of these. It is always good to remember that one buys steel by the tons and sells it by the foot, so it is essential to order (and verify) the coil thickness to be as close to the minimum thickness used in the design as possible.

The FRAMECAD system is the most used end-to-end system in the world. It has been developed to satisfy the needs of fabricators, GC’s, builders, panelizers and developers who were fed up with shipment delays, price hikes of steel profiles and lack of support. The

FRAMECAD system allows users to control their inventory and production. FRAMECAD caters for the small and large manufacturers as it offers dedicated profile systems as well as multi- profile systems. FRAMECAD is the only technology system provider that supplies engineering and detailing software with machines and other steel accessories. FRAMECAD offers support and services around the clock. FRAMECAD has highly experienced engineers and technicians that provide system training, engineering training, software training, factory training, etc. FRAMECAD has the fastest and most certified systems in the world.

For single family homes, one needs one or two profiles, the 3-1/2” and the 5-1/2” profiles. The 5-1/2” is mainly used for exterior walls while the 3-1/2” is used for interior walls, webbed floor joists, and trusses. The 5-1/2” profiles are essential in areas with high winds, high snow loads, or high seismic forces (earthquake prone regions). It is a myth that one needs 5-1/2” profiles to use more cavity insulation. That may be true for wood but not for steel. For the most part, the 3-1/2” steel profile is adequate for any single-family home in low to moderate environmental loads. The studs can be spaced at 24” on center or 16” on center if the design requires that. The 24” on center spacing provides the most efficient construction method for cold formed steel framing. The webbed joists and trusses produced with the 3-1/2” C-stud profile are adequate for all joists and trusses used in single family homes that are properly designed for cold-formed steel framing. Therefore, the entire home can be produced with one profile. The FRAMECAD systems that are needed for the construction of single family homes are the F325iT and the F450iT.

Have a question for our team? We can walk you through it.

Your one-stop shop with end-to-end solutions to run your business, better.

Design, Manufacture, Build and Deliver All the Way to the Jobsite

The Latest Insights and Trends in Construction Technology

Ready to Reframe How You Build?